Challenge

Improve accuracy of print and apply label process on garage door panels.

Solution

CTM 3600A-PA Label Printer Applicator, integration into current PLC system, and custom fixture.

Story

A garage door manufacturer was looking to improve the quality control on the label placement process for their garage door panels. The average garage door consists of 4 panels hinged together to form one large door. Each of these panels consists of the board itself and the metal end caps. The metal end caps are given a unique label depending on the garage door panels’ size, color, etc. The manufacturer frequently mislabeled the end caps, resulting in downtime from removing and relabeling the panel. The garage door manufacturer worked with the team at EMP in the past and reached out to them again to tackle this project.

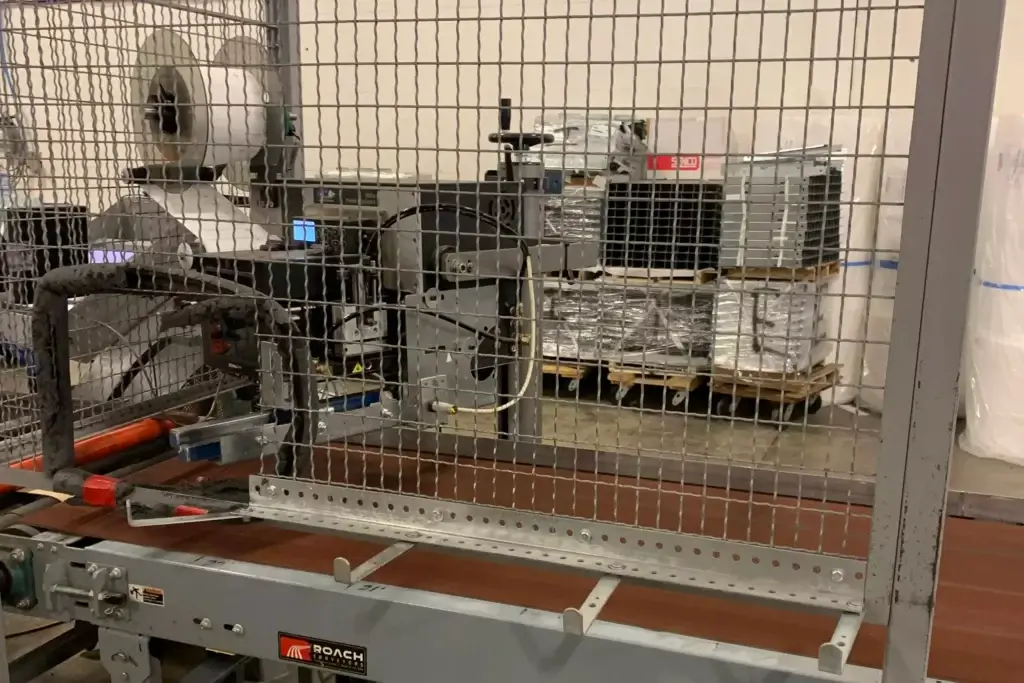

EMP observed that each panel coming down the line was unique and not part of a batch of panels, making labeling a difficult process. The EMP team quickly learned that the manual labeling process seemed to be causing the most errors. The EMP team proposed eliminating this with a CTM 3600A-PA label printer applicator. This applicator will print and apply the label in one step, eliminating the need to print labels, carry to the end caps, and manually place them. The EMP solution would also include an update on the communications between the PLC and printer to ensure that each label printed was for the right panel.

Initially, the customer wanted to integrate the label applicator inline, but they quickly realized that real estate was an issue in this area, so a separate fixture was created. Each end cap is inserted into the fixture and labeled by the CTM label printer applicator. This new system has dramatically reduced the manufacturer’s labeling errors.

Are you looking to improve your labeling process? Reach out to the team at EMP Tech Group today!