Problem

A linen supply company was manually sorting their customers’ returned linen by hand. This operation was exhausting company time and labor.

Solution

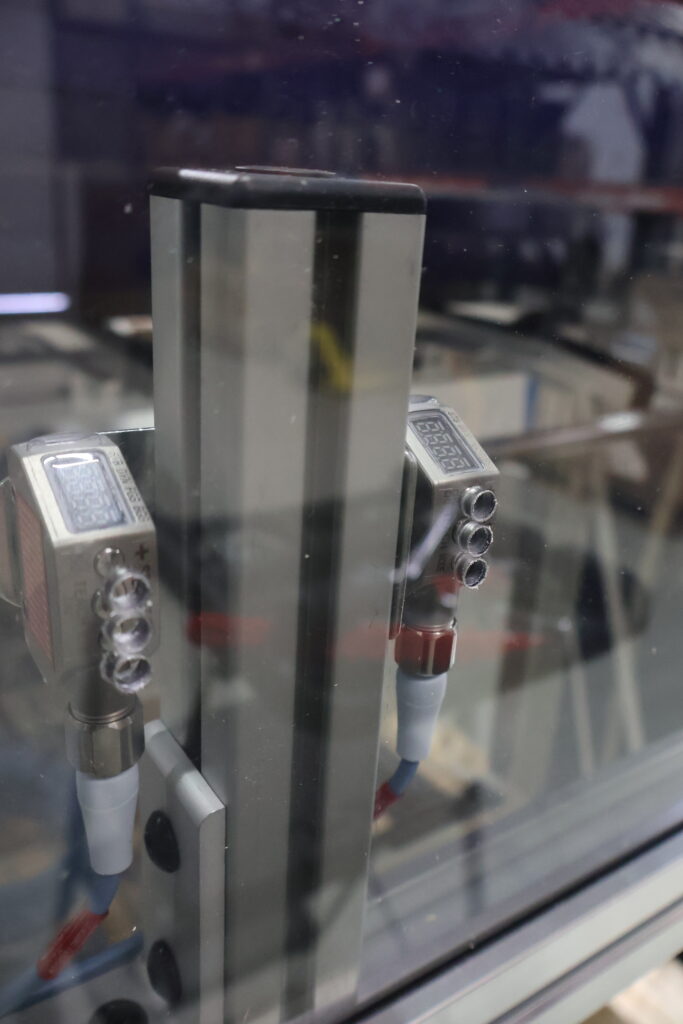

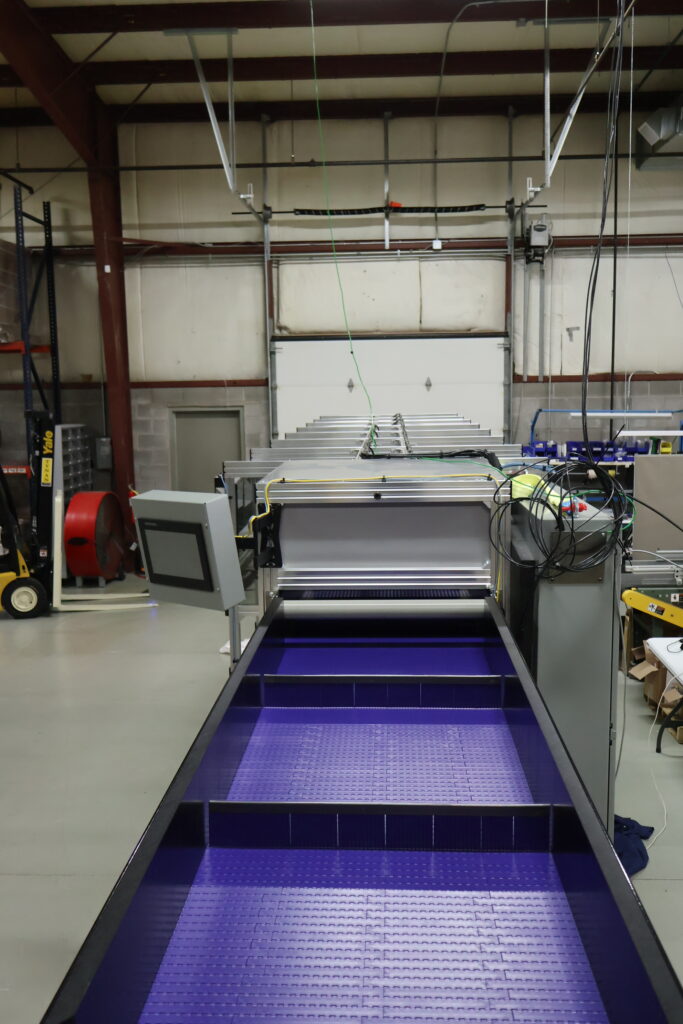

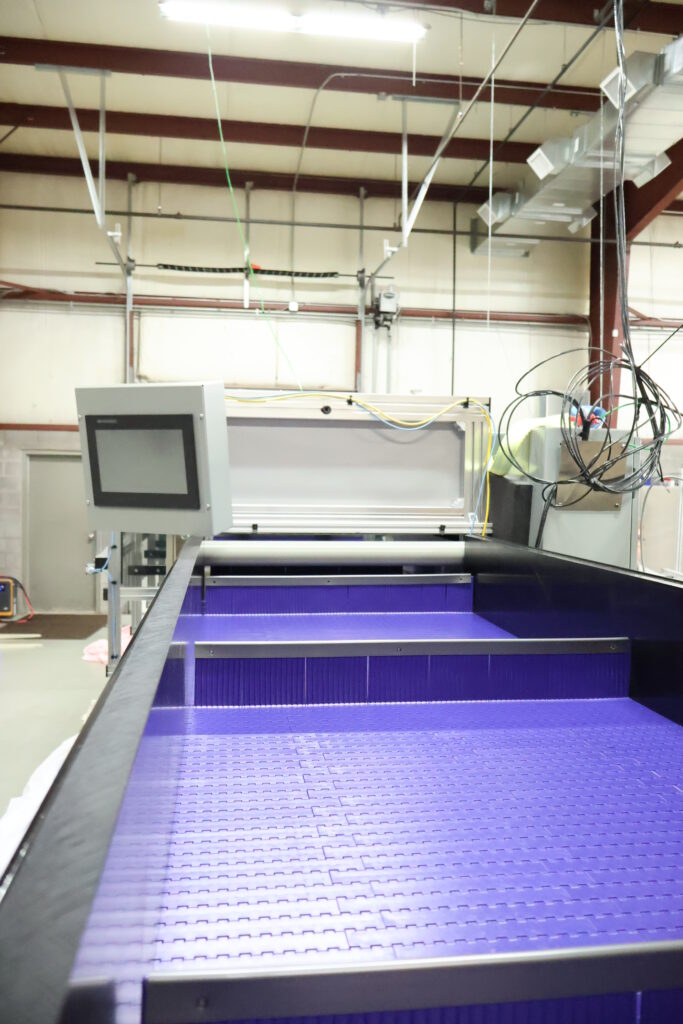

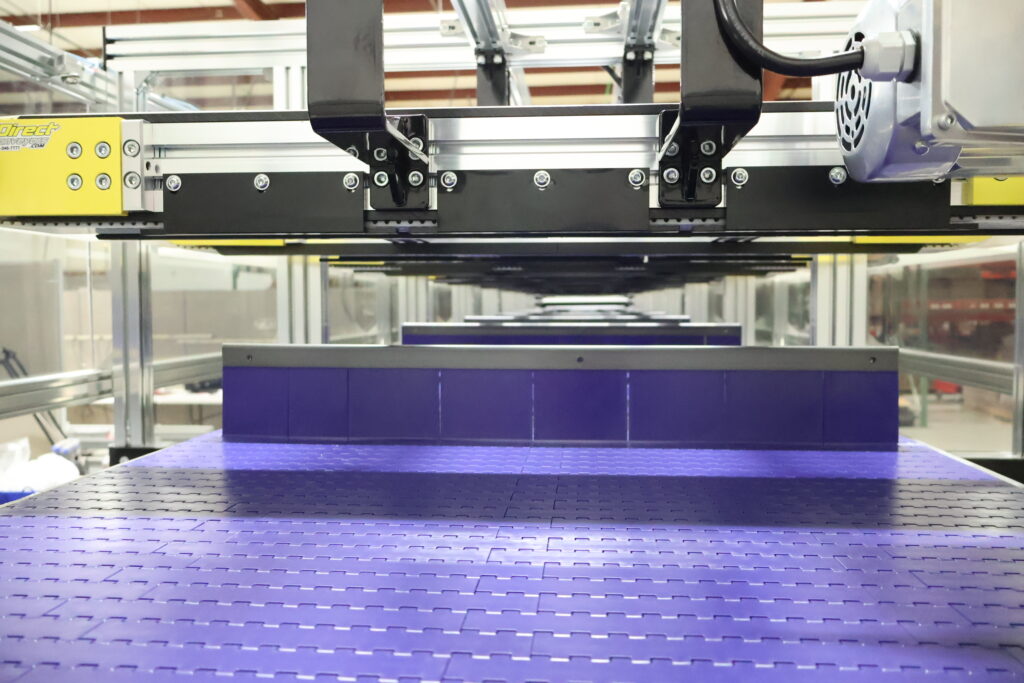

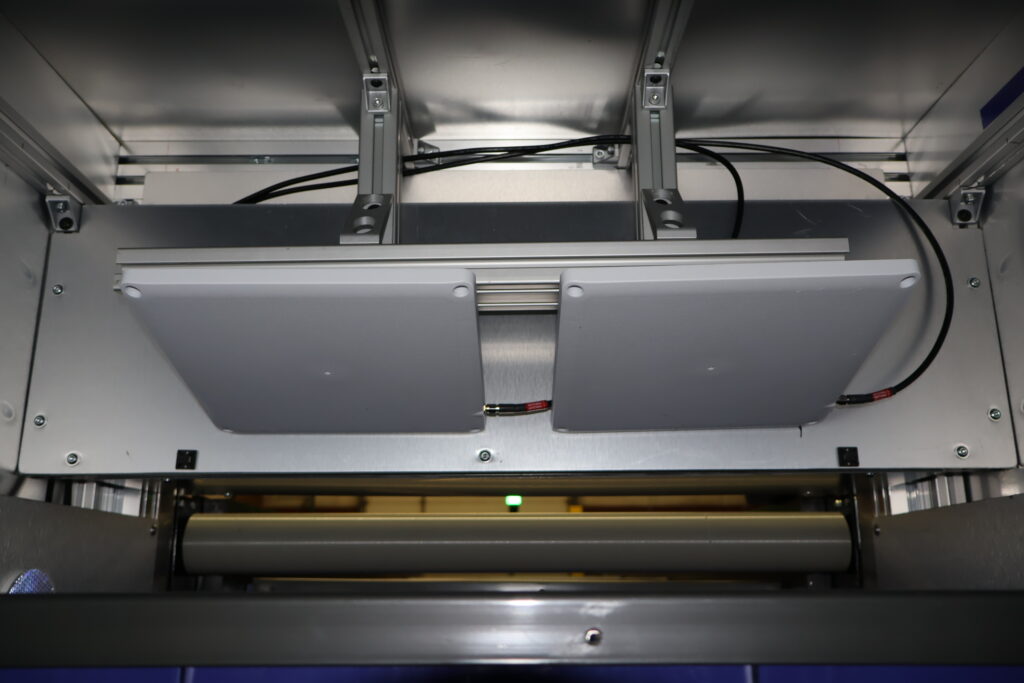

Design an automated system with an indexing conveyor line and a Zebra FX9600 RFID reader to read, identify, and sort linens into the proper bins for laundering and reuse.

Story

A customer was still sorting linens manually by dropping the linen load onto the floor and separating by hand. Luckily for EMP, they had already invested in RFID tags and a cloud-based tracking system which was a clear green light for automated RFID system. The automated solution featured a massive indexing conveyor (built offsite) that moves linens down a line. Each linen is read and identified by a Zebra FX9600 RFID reader, then directed, or pushed by paddles, off the line to the appropriate bin for laundering. The whole thing is powered and operated by a 60in X 48 in. control panel interface, the largest panel ever engineered and assembled by EMP. The result was a significant improvement in the speed and reliability of their linen sortation process, trimming hours from their operation to focus on more customers.

*See Below for More Pictures*