Problem

A packaging provider for a medical device company needed a semi-automatic labeling solution to apply pre-printed labels to a precise location on small boxes without disrupting their existing workflow.

Solution

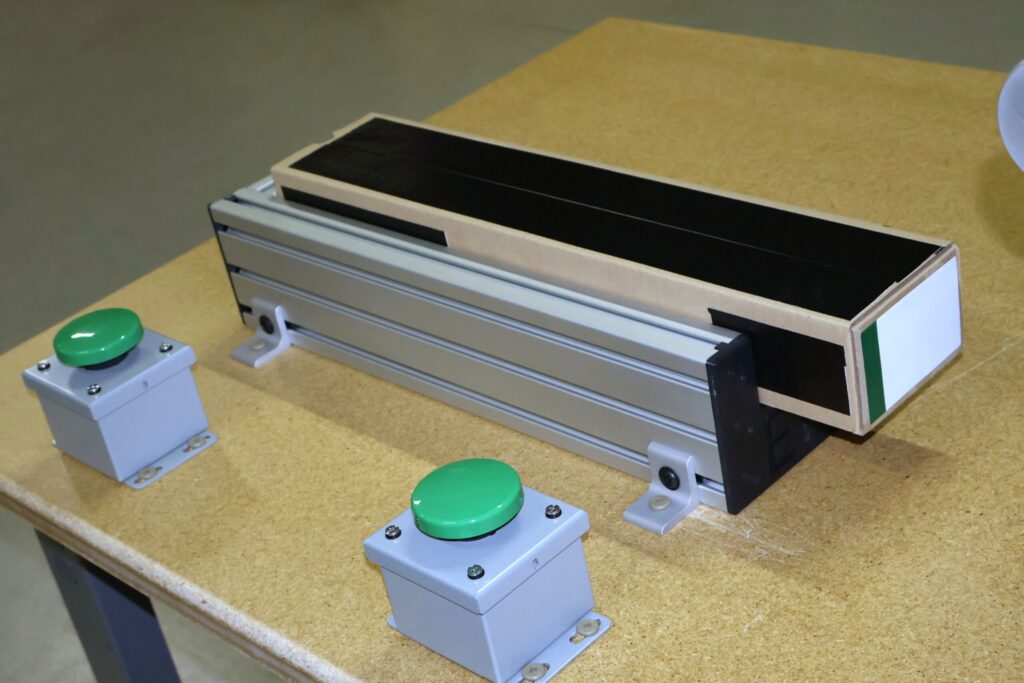

EMP engineers developed a custom labeling system using a CTM applicator with a 3D-Printed fixture for precise alignment and palm switches for safety. Built on an 80/20 aluminum frame, it includes a 6″ tamp stroke, stack light for status, and flexible I/O wiring for future upgrades.

Story

A long time customer approached EMP Tech Group with a need to re-label medical device packaging in a controlled, repeatable, and safe manner. Leveraging in-house 3D printing capabilities, EMP designed a snug-fitting fixture to hold each box in place, ensuring accurate label placement despite tight tolerances. To meet safety requirements, dual palm switches were integrated, requiring both hands to activate the applicator and prevent accidental operation. After a successful dry run with the customer, the system was fine-tuned and delivered as a turnkey solution. Another example of EMP Tech Group’s ability to deliver tailored, end-to-end automation solutions.