It has been a long road vetting logistics and manufacturing robot lines, trying to find one that we think is worthy of EMP selling to our customers. One that is practical to use, not crazy expensive, and would fit many of our customer’s needs.

Oh, by the way, a product manufacturer that embraces the technical reseller marketplace, sees the value of having tech savvy partners that can help customers integrate the technology locally. Partners that are capable of helping integrate the robots into existing software applications, build custom hardware to help the robot best fit in the application, and even service the robots as they enjoy a long life in the customers facility.

So, what line of robots did we choose to partner with, Bear Robotics is the answer. Isn’t Bear the South Korean robot company that is used mainly in food service? They were, but now that LG owns 51% of Bear Robotics, the future for the company is in manufacturing and logistics too.

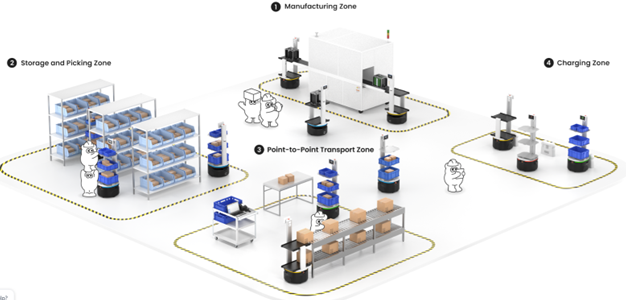

So now, more robust robots, with heavier payloads, are already on the market, and more are being developed. The best thing is the infrastructure that was already built to allow these robots to quickly and easily be trained in their new environment, and deployed in just a few hours in food service, easily translates to manufacturing and logistics.

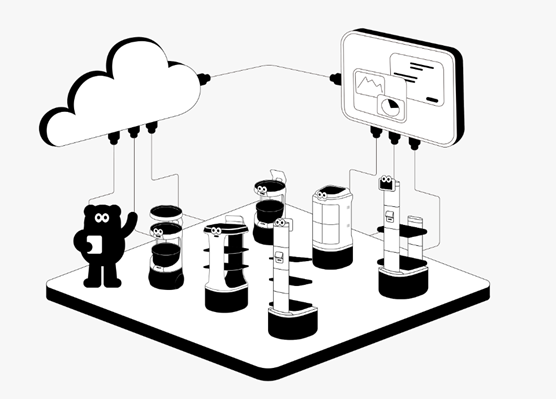

Since the robot has LiDAR and optical sensors, it learns its environment by being walked around the facility. The system also uses QR codes that are placed strategically around the facility that helps the robot keep its location. Then you show the robot key stops that you want it to make, identify and name the stops. You can also identify areas to be avoided by the robots.

It can be as simple as that, just start telling the robot through its screen, or from the Bear Cloud software to go from one location to another loaded with parts. Or you can also use the Bear Robotics API to have your existing business software summon the robots and send them on their next mission. EMP can of course help with the initial training and that interface work if desired.

Or EMP can help build fixtures so that parts are securely nested on the robot. We can also help by mounting tablet computers, printers, or RFID readers on the robots. These are really just a new tool in our tool belt to help you find solutions to your business needs.

If you want to learn more about these new robots and see how we can put them to work for you, www.emptechgroup.com is the best way to reach us.