Man, do we see this problem frequently. Customers befuddled why they cannot get their printer to do what they want. Changing settings, but the printer seems to have a mind of its own and ignores the setting changes that are being made on the display.

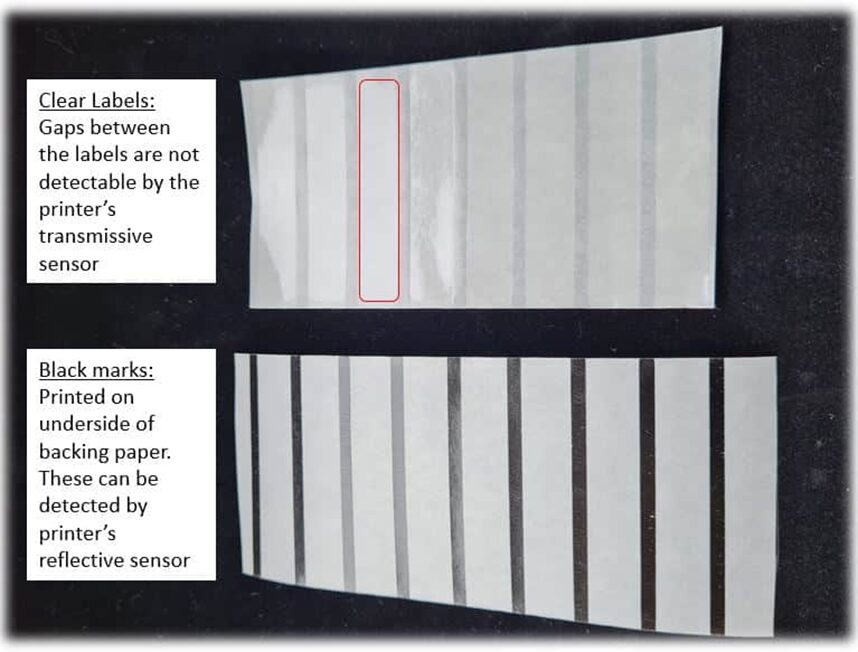

Then the printer reverts back to its bad behavior of printing too dark, or too slow, or looking for a ribbon that is not there, or looking for a label sense mark that isn’t there. The list goes on and on, the list of commands that could be sent down with a label job making printer settings happen that are not what you want.

If you are using a label design and print software like BarTender, you tend to have way more control over what printer setting commands are being sent to the printer with each and every label print job. But if an ERP or other enterprise software is driving your label printers directly, getting to those setting commands can be a challenge.

So why are these commands even being used in the first place. Usually, an IT organization is trying to manage the settings on the printer so that operators are not changing things and causing issues. But, sometimes an operator needs to make small changes to darkness, print speed or other settings to optimized label quality. That is then defeated every time a print job is sent to the printer, because the printer settings that come in the ZPL string always override any changes made through the display on the printer.

Making this worse is the fact that many software packages make the printer settings global so that every printer gets the same settings string with every print job. So, for example if you are using sense mark labels in one part of your operations, you now need to use sense mark labels everywhere.

We have good news though, our tech services team sees this issue so often, it is one of the first things that we think of when you call for help. www.emptechgroup.com is always the best place to reach us and see how we can help.