Problem

A company wanted to track their manufacturing process. All the way from raw materials to the final product, but they were still using a primitive system to identify and track the pallets.

Solution

Design a web application for inventory tracking in coordination with a Zebra TC73, a custom web application, and BarTender. This will allow the floor operator to scan the rolls of metal to be assigned to a pallet that can track the roll of metal through the whole process.

Story

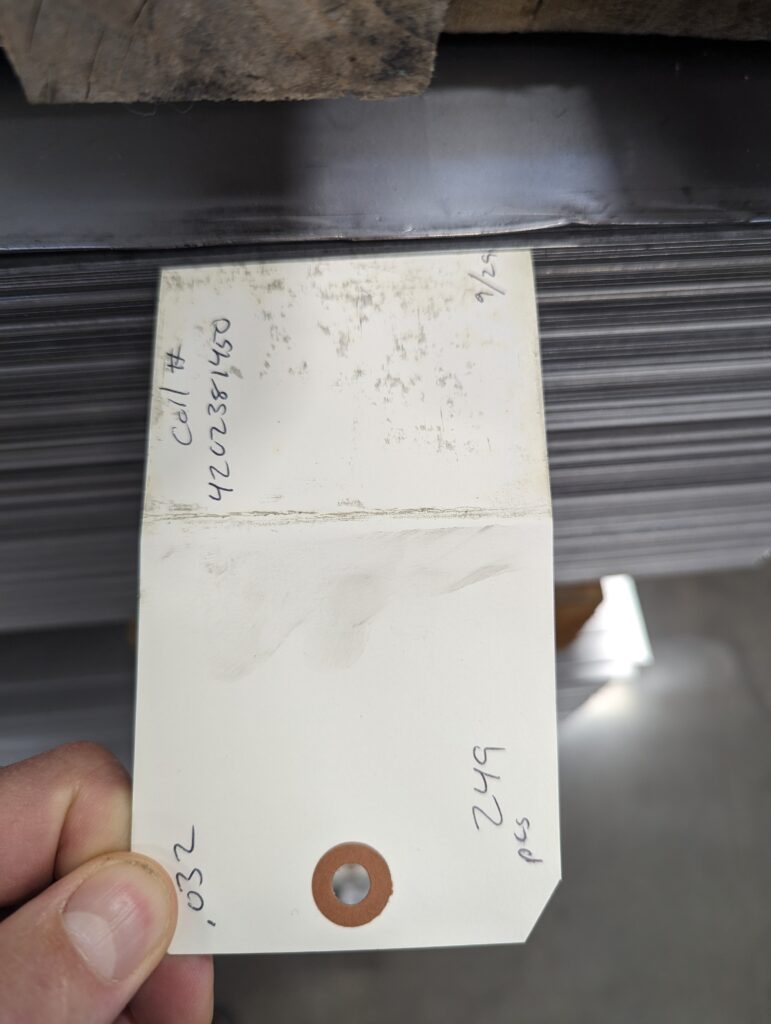

A company that makes barrels was having difficulty tracking rolls of sheet metal as they were formed into barrel parts. Before EMP arrived, the customer was using Quickbooks and handwritten labels (as shown above). After a scope of work, EMP created a solution. With BarTender integrated into their system, the operator uses a Zebra TC73 to scan the label on the sheet roll, which then prints out another label to be placed on the corresponding pallet. Then a custom web application designed by EMP allows the operator to scan the pallet label and A) assign which barrel part (top, bottom, sheet) will be made from that roll as well as B) which customer project that roll will be assigned to. Now when the pallet moves to the end of the line, they can verify by scanning the pallet as well as the label on the part that was manufactured to ensure no material was lost or incorrectly assigned.