Problem

A customer with a very large, very tall warehouse, wanted to install color rack labels to help employees better identify bays.

Solution

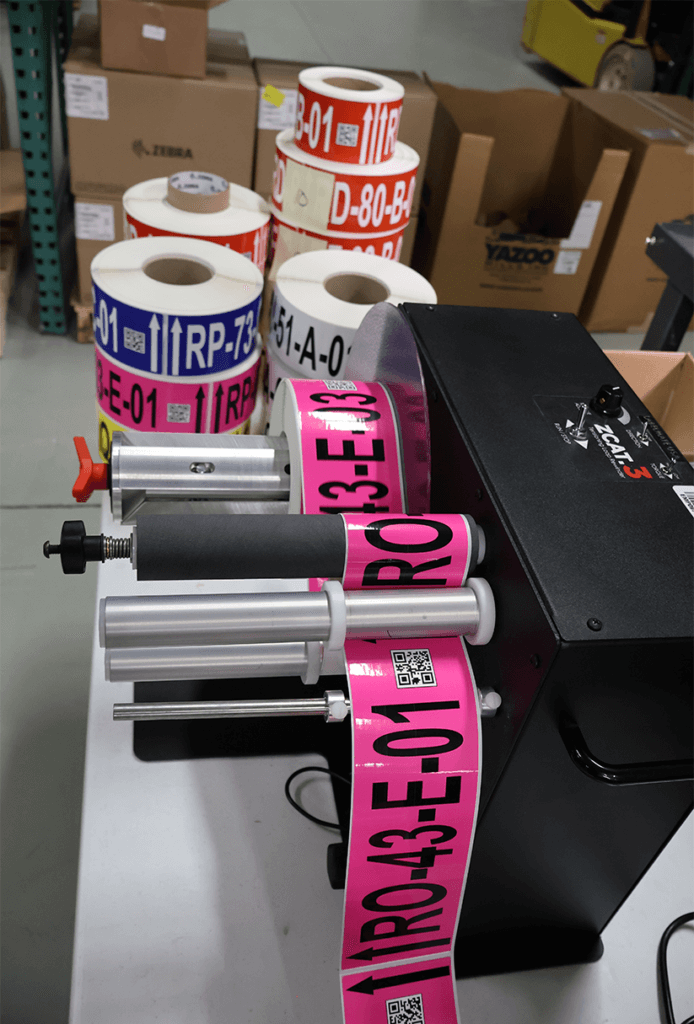

Create a non-stop color printing station at EMP to produce 20,000 labels in a couple of days. Install upon completion in customer’s facility.

Story

This particular customer had recently moved into their warehouse only to have installed temporary signage. They were wanting to display something more permanent, but also color coordinated for instantaneous recognition by their employees. Having installed numerous warehouse signage in the past EMP was happy to take on the solution. But they had never used color labels before. So, after analyzing the installation details and asking all the right questions, EMP chose an unwinder, a VIP Color VP550 Printer to print the labels, a Labelmate Z-CAT 3 to tightly wind labels back into spool after printing, and Seagull Scientific’s BarTender to design and create the labels catered towards the client’s preference.

EMP used their own specialty labels that were made specifically for color printing and manufactured at their label production facility here in central Indiana.

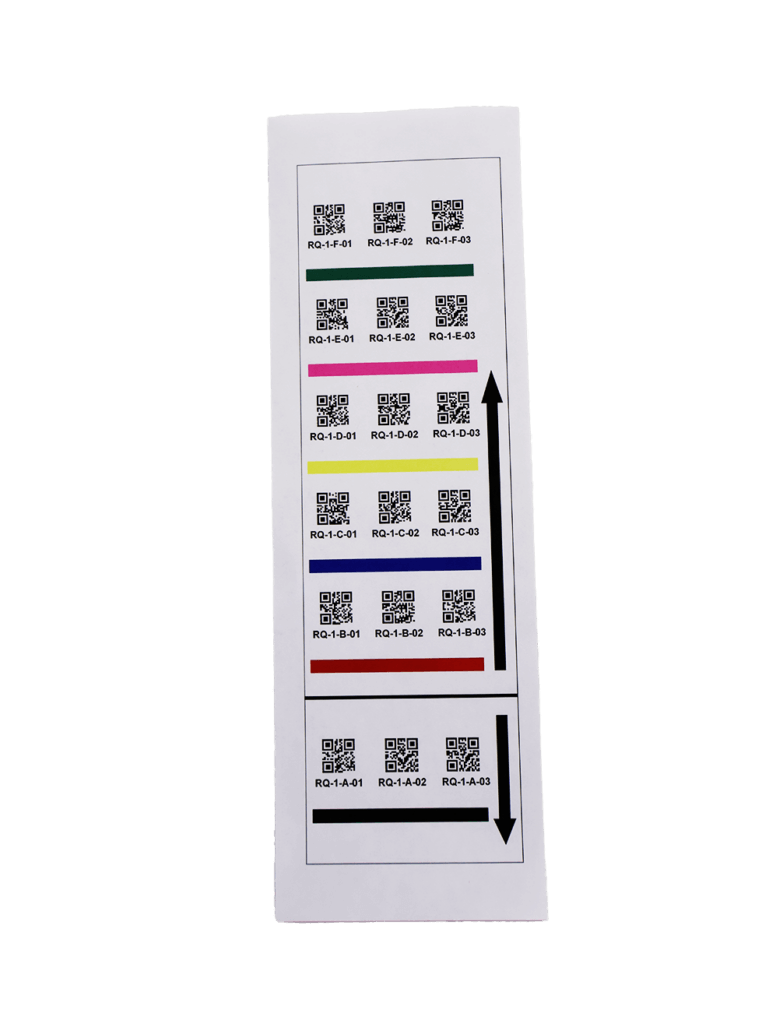

The size for each label is 3″x10″, varying in color from pink to green, etc. EMP also came up with the idea to have a vertical totem color coated chart for their employees to scan the barcode associated with the bay numbers that out of reach from their lifts. So, the actual job itself was not anything that another company hasn’t accomplished, however, it’s the level of organizational planning that sets EMP apart from its competitors in this scenario. It’s about planning the fastest, most reliable printing of the stickers. Asking the customer all the right little questions for a seamless process and planning for the installation for those labels once inside the facility.