Challenge

Real-time inspection of wire and cable manufacturing as it’s being spun off the production line at 500ft./min.

Solution

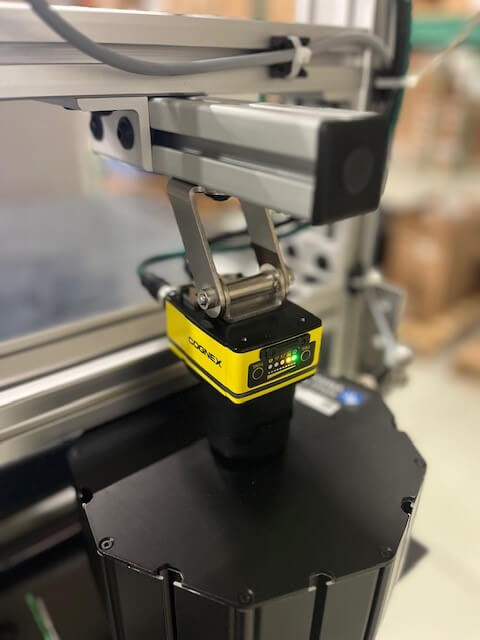

Design, build, and install a machine vision inspection system consisting of a Cognex In-Sight 7802, PLC, custom mounting structure and controls box that can check cable moving at high speeds.

Story

A company, with a CEO whose family has been in the production of wires and cables for over 100 years, came to us with an efficiency issue in their production line. In order to optimize their process on the backend, they wanted to make their quality control as efficient as possible while cutting time/labor and minimizing wasted materials. Previously, if they were to miss a couple feet of cable they’d have to go back and cut that section out, slowing down the final insulation and packaging process.

EMP Technicians chose the Cognex 7802 Color Machine Vision Camera (triggering every .5 seconds), a dome light (to reduce exposure and keep light balanced and inspection environment neutral), and a control box fixed with a PLC to operate the entire application. A red light will signal and production stops if it finds an incorrect orientation. They also installed software that captures all the images taken, allowing further analysis if there are reoccurring issues within the coating process of the wires. Are you in need of customized solutions for those continuing problems? Let EMP help guide you!