Problem

A customer had hired a third party labeling company to print and install rack labels within a facility. The hired company printed the labels, but then abandoned the installation leaving the logistics customer to halt operation until project completion.

Solution

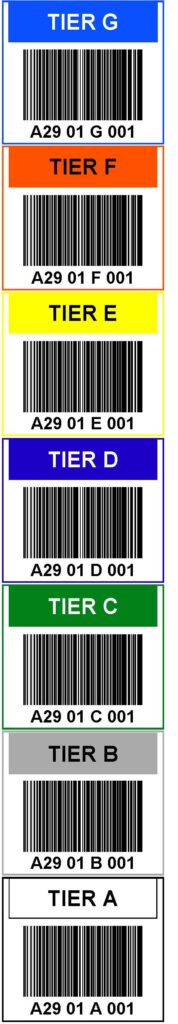

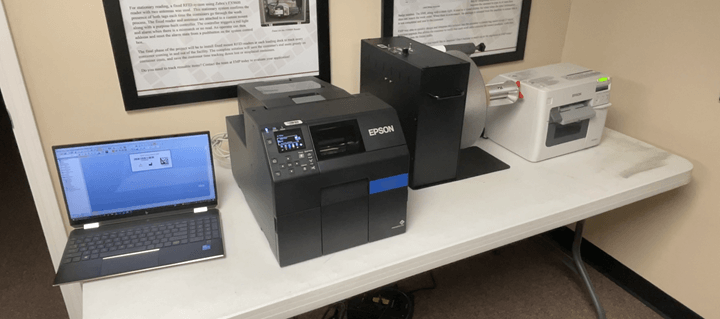

Take over the project starting with reprinting any labels that were of poor quality using an Epson CW-6000 Printer, overseeing the installation of the labels, and adding a vertical totem key to the bottom of each bay.

Story

A logistics customer that was operating inside of their customer’s warehouse was needing rack labels printed and installed to better identify and manage their customer’s products. They had hired a third party label company to print and install these labels, but for whatever reason that company printed their labels and then went radio silent leaving the logistics company at the 11th hour to complete the project before production could continue. EMP was called in and acted swiftly by first assessing the quality of the already printed labels as they were not EMP’s own. After noticing a fair amount of these labels were of poor quality and already peeling, EMP re-printed them using Seagull Scientific’s labeling software BarTender and an Epson CW-6000. In addition to the reprints, EMP printed vertical totem labels. After the rack labels themselves were installed, vertical label keys were installed at the bottom of the bay for easy scanning access allowing the operators to scan the isolated bay without having to use a crane. In a few days after being contacted, EMP was able to assess, fix, and carry out a project that otherwise would have been abandon by the original label company. Our heroes save the day again.