Problem

A customer aimed to incorporate a Zebra RFID Label Printer into their workflow, but encountered difficulties in ensuring seamless integration with their manufacturing equipment.

Solution

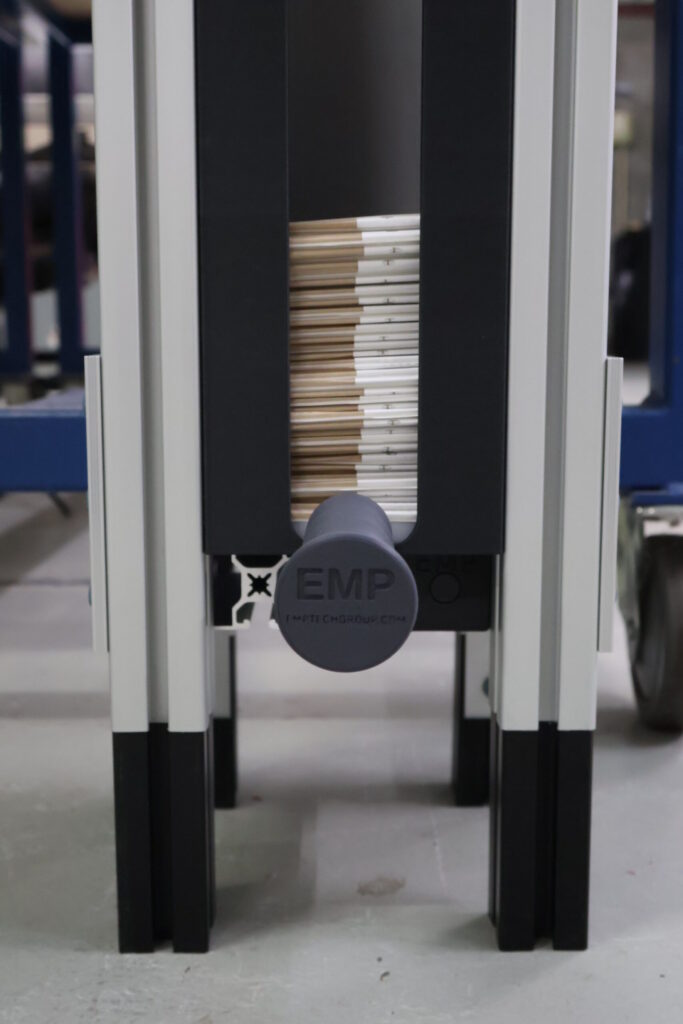

Design and 3D print a vertical catch tray to collect and autonomously fanfold RFID labels. Integrate the tray system into existing customer material by using 80/20 for the outer frame.

Story

A customer that was having issues incorporating a labeling system into their new production line. Using CAD software, EMP’s engineering team designed and created a 3D-printed fanfold tray that could nest together seamlessly and was printed from plastic to ensure it was non-conductive as to not interfere with the customer’s product. The tray was designed with ears to integrate with the 80/20 system, consolidating it into one piece. Additionally, a handy paddle was developed to easily pick up and manage the stacks of labels after they were printed and autonomously folded. The solution also included a custom 3D-printed ramp and end caps, ensuring compatibility with the customer’s existing 80/20 frame. This innovative approach provided a cost-effective and efficient solution, demonstrating EMP Tech Group’s ability to deliver tailored solutions for complex problems.