Problem

A pharmaceutical manufacturer needed to ensure the correct printed booklets were consistently matched to the right products on a high-speed line, eliminating errors from wrong materials or missing print while remaining flexible across changing jobs.

Solution

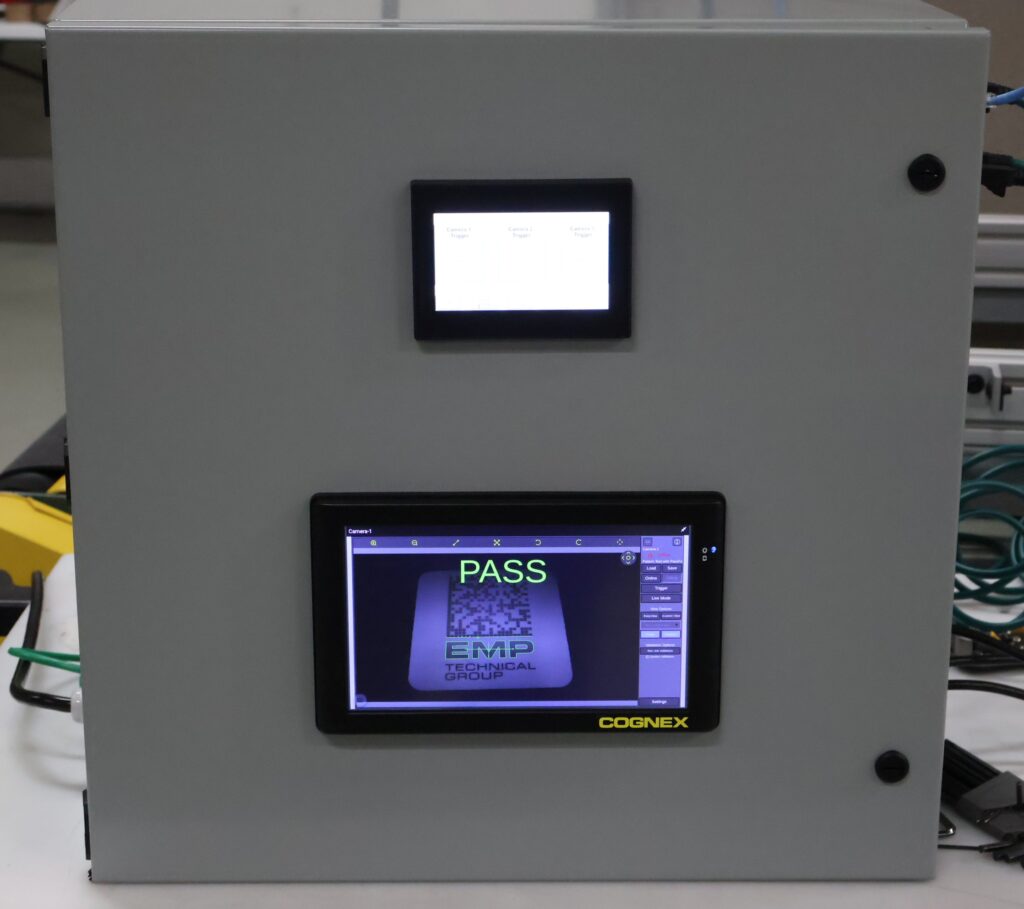

EMP implemented a stationary match-code and vision inspection system using Cognex cameras and a PLC-controlled cabinet engineered in-house. Operators can quickly train the system on known-good barcodes and visual patterns that reject or conduct line stops, delivering flexible, high-confidence inspection without heavy IT overhead.

Story

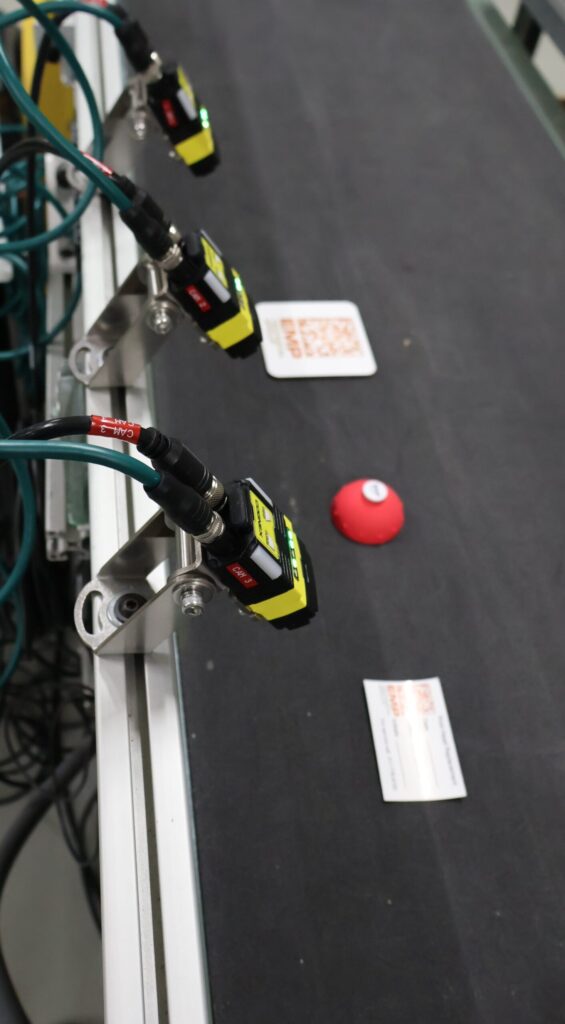

This project builds on more than two decades of match-code solutions EMP has delivered for this customer. What began as a simple barcode verification system has evolved into a flexible, vision-based inspection platform tailored to their pharmaceutical operations. The latest system uses multiple Cognex vision stations and a PLC-controlled enclosure to verify booklets in real time—checking barcodes, confirming print presence, or applying pattern matching when barcodes aren’t available.

Inside the custom-built enclosure, EMP integrated a Hoffman cabinet, Cognex controller, PLC with touchscreen interface, and three Cognex In-Sight cameras, all wired, programmed, and tested by EMP engineers before installation. Operators can easily select jobs, train cameras on known-good samples, adjust timing delays, and monitor pass/fail results in real time. All the while, EMP’s discrete I/O logic enables these smart pass/fail decisions without complex backend integration. This is a prime example of why match code remains one of EMP’s most powerful custom solutions. Whether mobile or stationary, barcode-based or vision-driven, EMP’s match-code systems help manufacturers ensure the right materials are used every time — with flexible, proven technology that grows alongside their operations.