We often say that we work in the niche of a niche. That assumes that IT itself is a niche, and we as Automated Identification and Data Collection (AIDC) experts, are a much smaller niche in the IT industry. AIDC is an old term, but all the technologies in our space (barcode scanners, RFID, OCR) are all automated ways to collect data. In this article, we want to better define this industry, its history, evolution, and current state.

In the Beginning

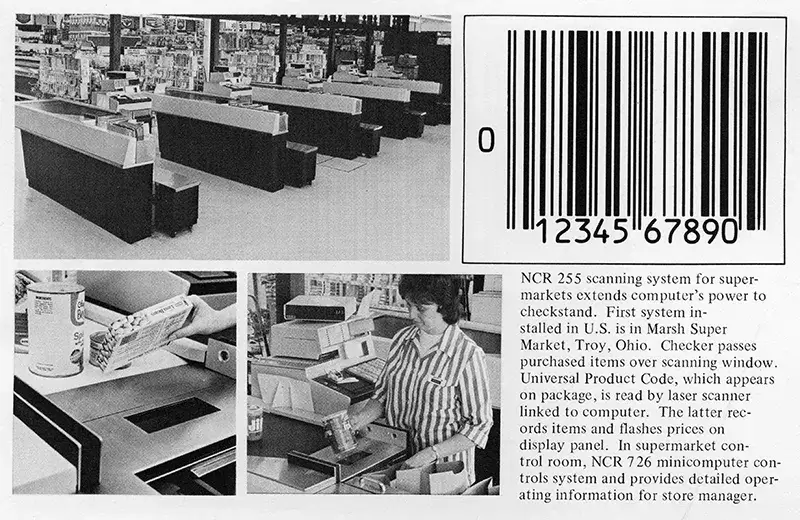

Now that we have defined who we are, let’s examine the history of the AIDC industry. In 1974, grocery stores started scanning UPC barcodes for pricing, as opposed to key entering pricing at the checkout. In 1984, the Auto Industry Action Group (AIAG) standardized Code 39, and a specific label format to be used for all raw materials being supplied throughout the industry.

When the grocery store industry started barcoding, the customer count was low enough and the technology new enough that the equipment manufacturers handled sales and integration themselves. But when the auto industry started to use the technology and mandated its use through all the supply chain tiers, the need for third party companies to help sell and integrate the technology arose. This doesn’t even mention other industries such as military, pharmaceutical, medical device, etc., that also started to use barcoding during this time period.

So, the “AutoID Value Added Reseller” (VAR) was born. An entire industry specializing in AIDC as well as the printing side of the business started to develop. By the end of the 1990’s, there were thousands of companies in this space globally, helping customers integrate barcoding, and keep the equipment that prints labels and scans barcodes up and running. The value add was in helping the customers with the setup, software, and interfaces needed to integrate this technology into their operations. Not to mention the service work on label printers.

Starting up one of these small local to regional technology businesses was quick and inexpensive. There is little capital equipment needed, just a small office, some expertise, a vehicle to go visit customers and some tools to fix label printers.

The Gold Rush

Then the gold rush happened in the early 2000’s: the internet. All of the sudden, this face to face, on premise business, was threatened by customers purchasing these products online at steeply discounted prices. Discounted because the e-tailer did not need to carry any inventory, employ any technology experts, or take the time and cost to visit the customer. Just a low price on the internet. The birth of the e-tailer, Barcode Barn, Barcode Bonanza, Cheap Barcodes, etc. happened. Ship the product from one of the industries distributors and forget about it.

And forget about how they treated the customer. “If you can’t get it to work, call the manufacturer. We just shipped you the part number that you asked for and we can’t afford tech support”. Suddenly the manufacturers in our industry found themselves overwhelmed with unhappy customers who either ordered the wrong product or couldn’t figure out how to get the right product to work.

Early in the gold rush some of the manufacturers declared that the VAR was dead, that all customers would purchase all AIDC products on the internet. And for some products that can be done, but for many of the more complex products, an expert who can help integrate mobile computers, machine vision, RFID, fixed mount barcode scanners are needed by even the most sophisticated customers.

Enter MAP Pricing

After about a decade of this situation, the manufacturers were growing tired of the constant erosion of the price of their products. The burden of trying to support customers who purchased these products online from a price catalog company that had no idea what they were selling was growing. So the leaders in the AutoID industry took a page out of the Apple playbook and started controlling the Minimum Advertised Price (MAP) that e-tailers could charge. They also began to realize what the Value Add was, in the Value-Added Resellers (VAR). They started to give bigger discounts to the companies who were helping customers choose the right products for their application and helping integrate these products into their operations. Thus, taking on the sales, integration, and support burden from the manufacturer.

The Roll Up

As we entered the 2010’s after the financial crisis of 2008, a lot of investment money came into the market. Purchasing technology businesses, mashing them together, and reselling the consolidated product became a thing. The AIDC industry was no exception and many of the thousands of Value-Added Resellers, even E-tailers, were gobbled up and compounded into larger companies. The problem is that it was difficult to scale the technological side of the business. Many of the E-tail companies that were rolling up businesses, tried to purchase technology, integration-based partners, and bring that capability into their offerings. But it never seemed to work out well.

One problem is the niche of a niche situation. You can’t go down to the barcode union hall and hire a couple more barcode experts. These technology experts must be trained in house and that takes time. Even the major universities are not really covering this technology in their curriculum. Back in the 1990’s there were some classes in the field. Purdue University even had a master’s degree program, but not these days.

The Pandemic

A funny thing happened in the Pandemic. Most of the manufacturing base not only stayed in operation, but they also experienced a boom. The need for AIDC products grew along with this. IT departments started to realize that they were not allowed on their own production floors, but outside IT vendors could get access to the plant. Add to that, the maturation of cloud-based software products to help manage mobile computers, barcode scanners and label printers, and the need for in-house IT to support these products diminished. So once again, the true VAR’s role got stronger, not only helping to specify and integrate products, but also to help support technology products on an ongoing basis.

In a larger view of our industry the major players, who were all about retail and hospitality, saw those markets take a huge hit during the pandemic. Making the very unglamorous manufacturing and logistics space seem suddenly appealing.

The Present State

So, here we are in 2023. The equipment manufacturers are placing a high value on the true integration partners. Realizing that the E-tailers are merely a convenience purchase for media, and basic technology products that do not require expertise or integration skills. Customers are increasingly relying on outside companies to help support operations. The industry roll-up has slowed to a crawl as investment dollars have started to dry up. Companies like the EMP Tech Group have weathered all these industry storms and come out larger and more capable than ever.

Recognizing the need for integration partners and the customers desire for end-to-end solutions, companies like Zebra and Honeywell are trying to play match maker between VARs and software companies. And sometimes like the need for a WMS software solution, this is a good marriage. But many times, the lower technology VARs and the canned software companies end up offering the customer a solution that is way overkill for what they need. That is because canned software partners don’t have custom streamlined interface solutions that many applications need. And the lower-level VAR has not developed the in-house expertise to produce these custom interfaces for themselves.

Enter the EMP Tech Group. Sometimes, a piece of existing software is the way to go. But sometimes, a piece of custom software or middleware is what is needed to best serve the customer’s needs. Our sales process is to first try to find a way for the customer’s existing software to get the job done. If not, then try to find off the shelf software. And finally, only as a last resort, will we look at building software from scratch for a customer application.

Also, the software side of the business itself has grown. Not so much application software, but the ancillary software needed for the AIDC space. Label printing software that is enterprise grade is more important than ever. Having standardized label formats that your company can print from anywhere in your operations and even your suppliers can access and print for products that they are shipping to you, is more important than ever. Also, MDM or mobile device management software is gaining in our industry. The ability for a customer to manage hundreds or even thousands of devices across the globe from a single dashboard is now a reality.

The Future

The manufacturers in our AIDC industry have consolidated greatly over the years. Most of the companies that started this industry are long gone and only a few large players remain. This may happen with the AIDC VAR side of our business, but not soon. Being an entrepreneur is still a highly coveted role in our society and as long as starting up a business in our space is relatively easy and inexpensive, there will be people wanting to take the plunge. Come on in, the water is warm. All we ask is that you operate with integrity, and value the customer above yourself. If you can do that, you will succeed.