Choosing the right barcode scanner for your application can be a bit confusing. Let us help you decide which scanner is suitable for you!

First, you can break the answers down into these categories.

- 1D only or 1D and 2D Scanner

- Corded or Cordless

- Presentation or Handheld

- Industrial or Commercial

- Paper Based Barcode or Direct Part Mark

- Long Range vs Short Range

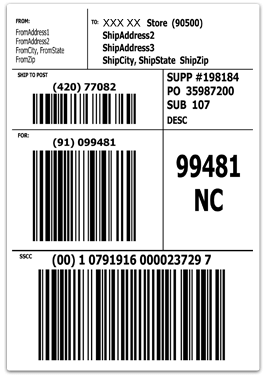

1D only or 1D and 2D Scanner

For a few years now, we have been advocating for only purchasing imager-based barcode scanners to future-proof your purchase. You may only be scanning 1D barcodes today, but inevitably, you will have a requirement to scan 2D at some point down the road. Not to mention that 1D barcodes scan much faster and without the needed orientation between the barcode and scanner that 1D only scanners require.

Corded or Cordless

Corded or cordless is pretty self-evident; if your scanning station does not have all of the barcodes in your hand and you have to walk away from the PC to scan, cordless is the way to go.

Presentation or Handheld

The one that many people do not think about is presentation scanners. It is often far better to hold the barcode under a stationary scanner to read the code without having to pick a handheld scanner up. To sweeten the deal, a high-speed conveyor line scanner can be used, and you can practically walk the barcode under the scanner to get it to read the code. One customer was so happy with this approach; he commented that you only need to get the barcode in the same room with the scanner, and it scans.

Industrial or Commercial

Industrial vs. commercial is not always an obvious choice. Scanning in a freezer or outdoors makes the decision easy for industrial. Scanning in an office environment makes commercial-grade the obvious choice. But there is a lot of middle ground between those two, and sometimes the customer’s appetite for spending a little more for a scanner that will never break down is the deciding factor.

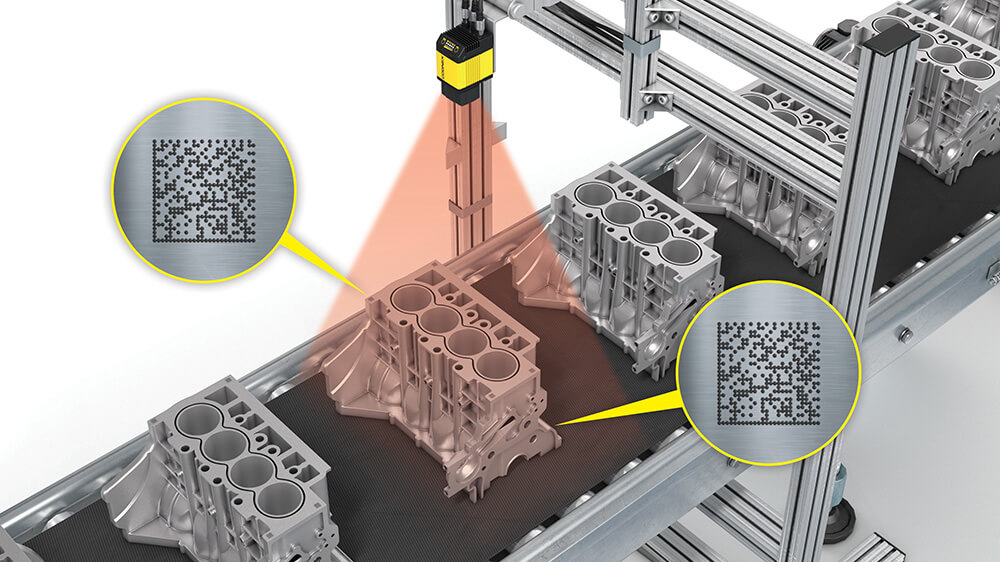

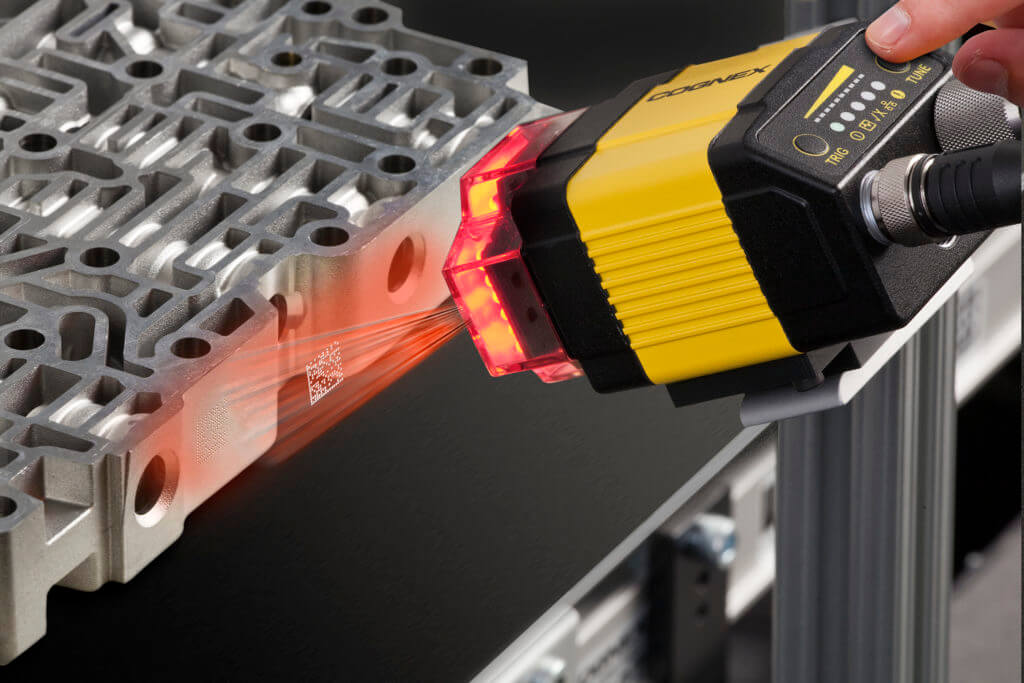

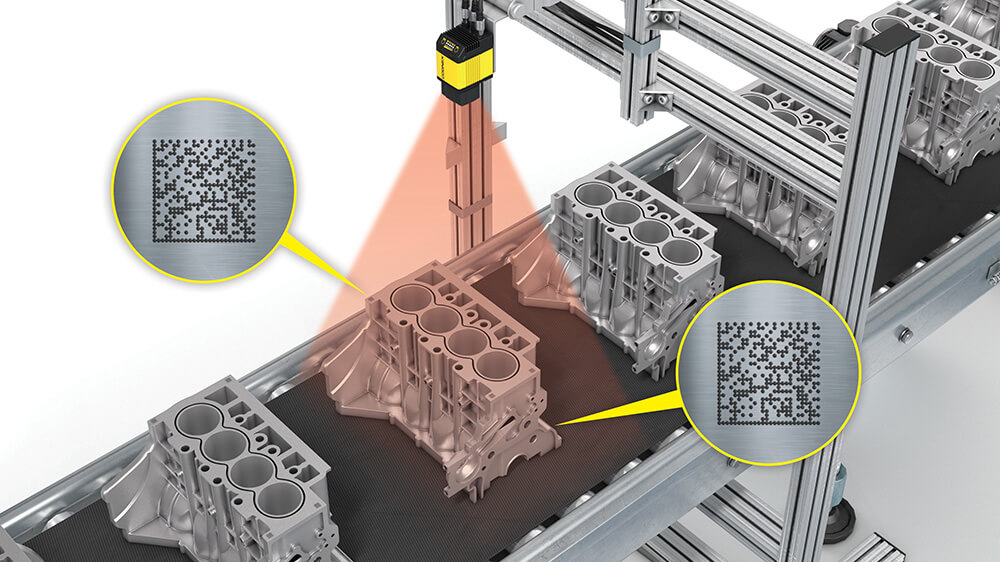

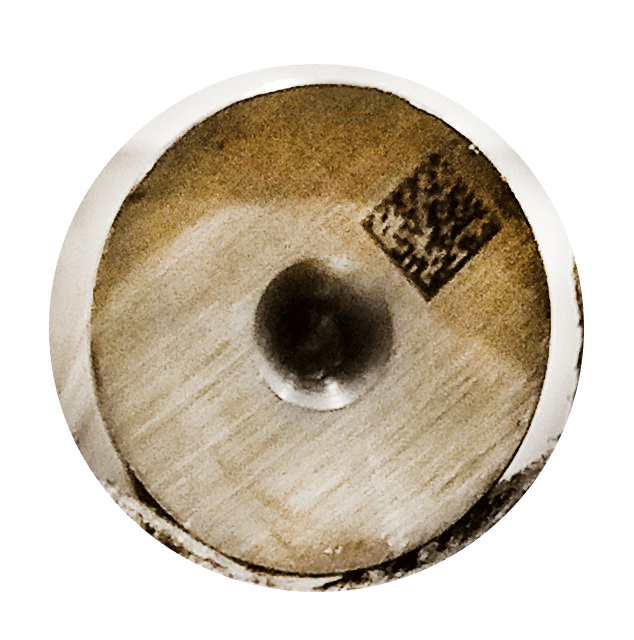

Paper-Based Bar Code or Direct Part Mark

Direct part mark scanners are not an easy decision. There is a good, better, best decision to be made there, and the cost difference per scanner is drastic. Sometimes, the decision can only be made after testing a few scanners to see how much scanning horsepower is needed to read your direct part mark. Also, just being able to read it on a good day is not the way to go. Laser markers and dot peen will degrade over time. Metal surfaces can be somewhat clean in one batch but slightly textured or even corroded the next. A DPM scanner that reads your marks even on a bad day is needed. On the other hand, we have gone into applications where an expensive scanner was recommended to the customer only to find out that a lower-end reader would easily do the job.

Long Range vs Short Range

In the past few years, long-range scanners have also become capable of reading short-range. It used to be that you had to have long arms to get a long-range scanner to read a small barcode. Recently, however, Zebra has added a short-range scanner to their long-range unit. The scanner does both simultaneously, ensuring that you can read that high rack barcode from a long distance and the small barcode up close, working very well and scanning quickly. Battery life is the only downside, but today’s batteries are so good that you will not notice the difference. There is also a rare case requiring the ability to scan very tiny barcodes, primarily in laboratory environments scanning specimens.

Bottom line, you need an expert to help you navigate this and someone you can trust. We are your trusted source when choosing the right barcode scanner for your application.