Once a month, we poll our tech support team and ask them for a tech tip. Sometimes the answer takes some time and thought, and sometimes the answer comes easily. This month was an easy answer because lately, we have been helping several customers with printer settings issues only to find that the data string coming from their application is overwriting their settings.

This is a little down in the weeds, but all label printers have a command language to drive the printer. If it is a Zebra printer, it is ZPL. Sato printers use SBPL. Older Honeywell printers use the Intermec language called IPL. Of course, there is no common language to drive them all, but most printers will do an emulation where you can feed them the other brands’ language, and they interpret it and print a label.

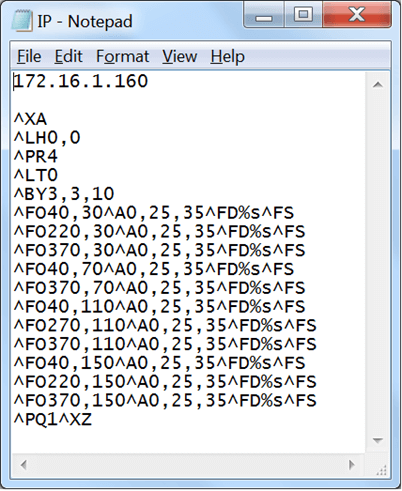

If you are using a label design and print software like BarTender, it does all the work to generate this printer code. But sometimes, customers, or even we at EMP, will manually create this data file for the printer.

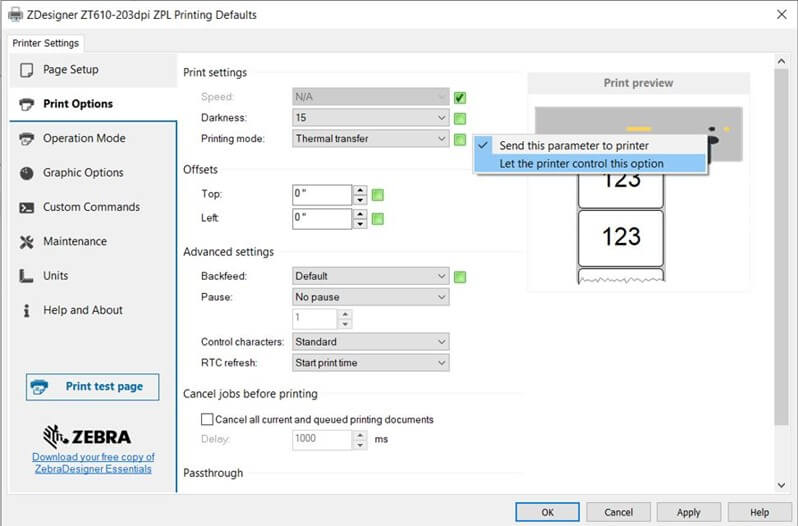

To get to the point, one of the things you can do with this code, either manually written or from a software package, is to set printer settings in the code that will overwrite any operator input of settings on the printer. For example, the code tells the printer to print at 2 inches per second. The operator keeps trying to speed the printer up by changing the settings in the menu system on the printer. But every time they print, the label comes out at 2 inches per second.

The same applies to darkness, top-of-form offset, thermal or direct printing, and gap versus mark sensing; the printer string can set several settings. You can change them in the printer, but every time you print a label, the data string changes them back to its settings.

This can be good if you know what the settings should be and want to control them from the label format. But anything that comes up while operating the printer that might need a setting change will not work. We have customers that must purchase labels with sense marks and cannot use gap labels because the label software demands the mark be there. Even if they change the printer to gap, it gets overwritten every time you print a label.

The main message is to be aware of this. When you are having issues that seem like the printer is broken because it won’t accept any of the changes you are making to the settings, it might be that your label format is overwriting those changes, and there is nothing wrong with the printer.

Our group is full of experts on these matters and is here for you. We even have several engineers that can write this printer code from scratch. Contact us to see how our team can help!