Problem

A customer faced difficulties maintaining accuracy and efficiency while manually applying batch-printed labels to a variety of product boxes.

Solution

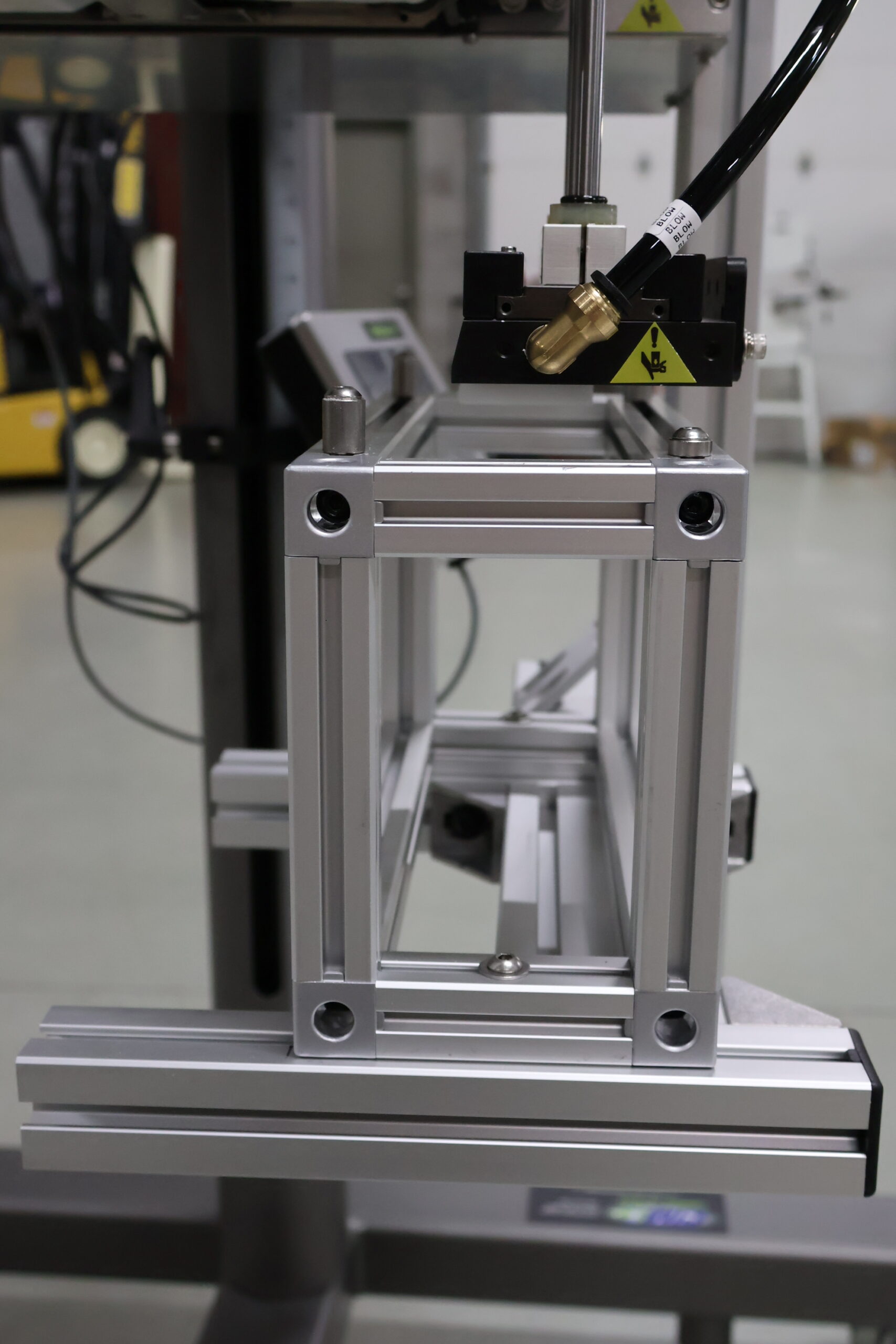

EMP implemented a CTM 3600a-PA Printer Applicator to automate labeling, utilizing a Zebra Print Engine with BarTender Labeling Software and 3D-printed custom fixtured templates for various product boxes.

Story

An auto parts manufacturer was experiencing continuous errors in the labeling process at one of their distribution centers. With various small part boxes needing individual labels, they created an assembly line workflow that involved printing labels in batches, with one employee peeling the labels and another applying them. This process also resulted in a surplus of labels. EMP devised a streamlined solution for real-time label application using a semi-automatic labeling process with a CTM Label Applicator fixed with a Zebra Print Engine. They built a cradled tower with interchangeable custom 3D-printed plastic fixtures for different part boxes and attached a pedal trigger for on demand labeling. Operators can easily switch fixtures, adjust settings on the display interface, and press the pedal to label efficiently. This solution resulted in a faster, error-free workflow.