Problem

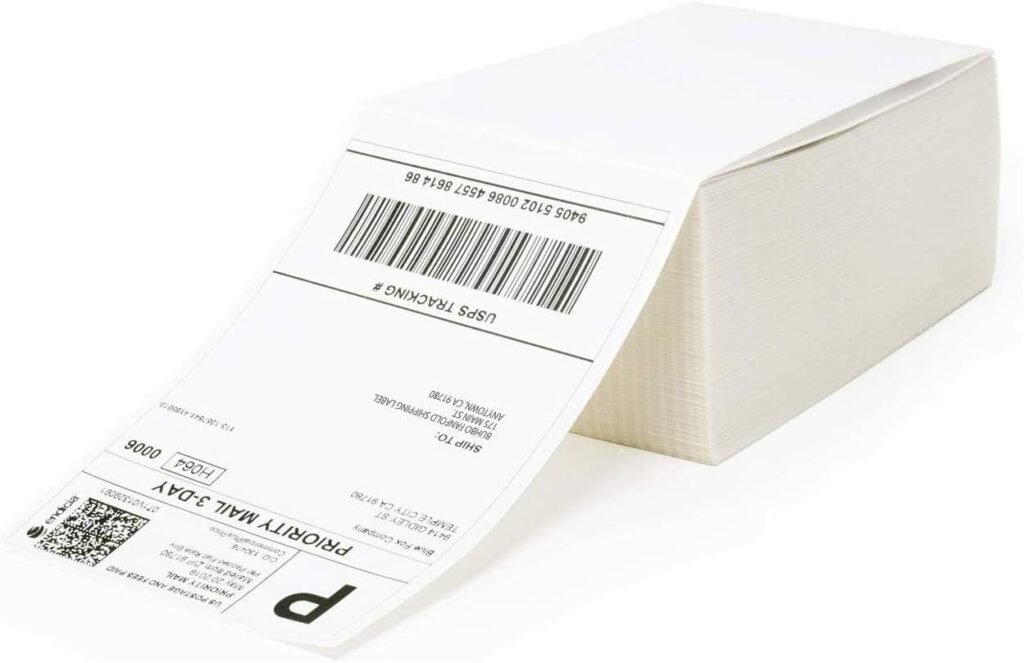

A warehouse distribution center was needing a more efficient way of maintaining and reloading their printers with fanfold labels in a small operational area.

Solution

Customize an EMP Printer Stand with shelves attached directly behind the printers. This will allow fanfold labels to be fed into the back minimizing printer error and the ability to print more labels unattended. The Printer Stand in itself will also allow for maximization of space and accessibility.

Story

A tire manufacturing company was using a third party to ship their products. This logistics company had three industrial Zebra printers without any access for maintenance or media replacement. On top of that, the fan fold labels were having to be fed into the printer, but they were having to position the box beside the printer which was leading to issues in printer alignment. The clearest solution was the installation of EMP Printer Stands. These Printer Stands solve many operational issues. 1) They cut down on printer storage in small areas, allowing for a maximum of 3 printers in a tight vertical space and 2) The shelves slide out to allow for proper reloading of media and maintenance. The last solution needed was space for the boxes feeding labels into the backs of the printers. After acquiring some spatial dimensions, the printer models, and the size of the boxes, EMP engineers were able to draw up a custom design solution. By using 80/20, they were able to build and then bolt on shelves to the back of the stand allowing for perfect placement for label storage. Now they can load the fan labels, and essentially walk away as thousands of labels are printed.