Problem

A manufacturing company that makes garage doors was having trouble with accurately labeling the correct parts to the correlating identifying labels.

Solution

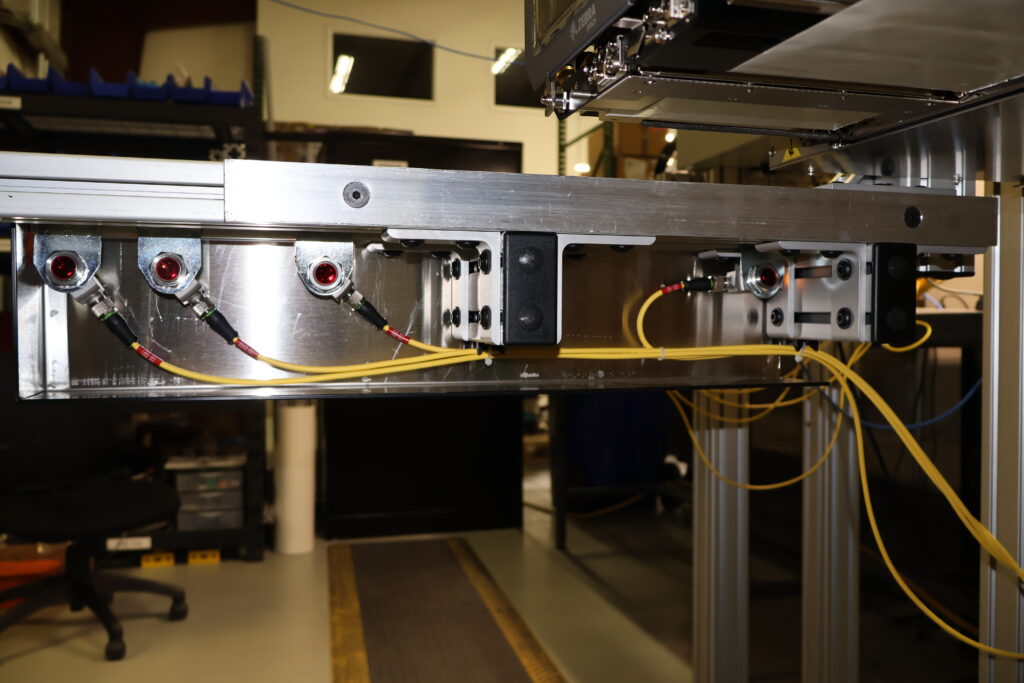

Designed, engineered, and built an Automated Print and Apply Solution. The key components were a large custom-built PLC and an array of sensors for precise placement to prompt a label applicator that will automatically apply labels consistently.

Story

A garage door company that manufactures its own parts for assembly was having complications with correctly being able to identify their newly manufactured parts, specifically the brackets. These brackets have various different sizes and were either being labeled with the wrong labels, or they were being applied inconsistently. Many types of hardware and software went into this large project. Starting with a Print Applicator from CTM Labeling Systems, EMP added a Zebra print engine, as well as a custom application built into the PLC. The operator picks the correct sized bracket the system is calling for and slides the part onto an 80/20 frame, activating four sensors that determine if it’s the correct size bracket. A green go-ahead light appears, and the label is automatically applied exactly where it needs to be for distribution. Now they have a solution that helps minimize fault, increases productivity, and creates efficiency throughout their operations.

Watch the video below to see a demonstration of this massive Print and Apply project!