Challenge

Automate receiving and location tracking of large steel coils.

Solution

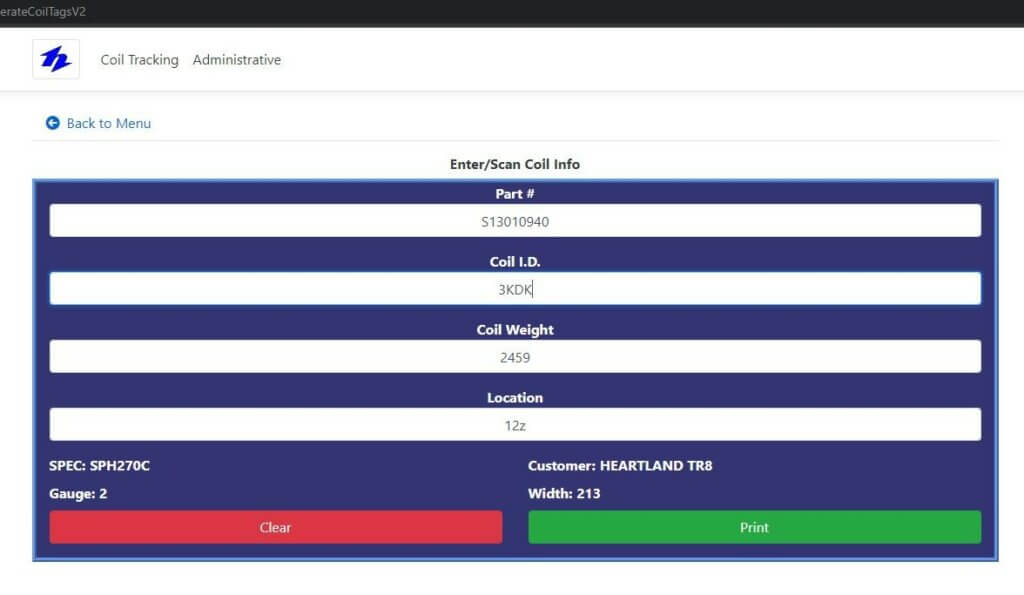

Custom application to store coil information (serial number, weight, location, etc…) as it is received.

Story

Many automotive components are manufactured out of steel. Often, this steel arrives at a facility in a large coil where it is then cut and stamped into a specific automotive part. One of these stamping facilities was having a hard time keeping track of these large coils throughout their facility.

The current process involved receiving the large, steel coils, weighing the coils, assigning them a location in the plant, and handwriting all this information on a tag. Unfortunately, this method led to many mistakes, misplaced coils, and incorrect weights. The customer wanted to automate this process so they could have a database of each steel coil received instead of a wall of paper tags. They reached out to their longtime partner of automation, EMP Technical Group.

After assessing the situation, EMP knew right away that this would require a custom program to store all the information. The solution that EMP provided involved an ultra-rugged Zebra handheld barcode scanner that scans the initial tag’s barcode to obtain any information available. Any missing data is manually entered into the program on a PC. Next, the coil is weighed and verified against the weight given by the vendor. Any discrepancies are taken up with the vendor. Once the information is scanned/entered in, a tag is printed, and the data is entered into an online database. This database is used throughout the plant to locate each steel coil. It has saved the company a significant amount of time searching for each coil.

Are you looking to automate your process today? Reach out to the team at EMP Technical Group!