Steel Tracking Solution

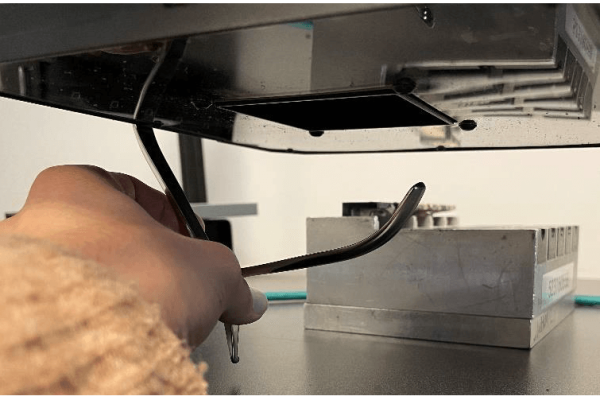

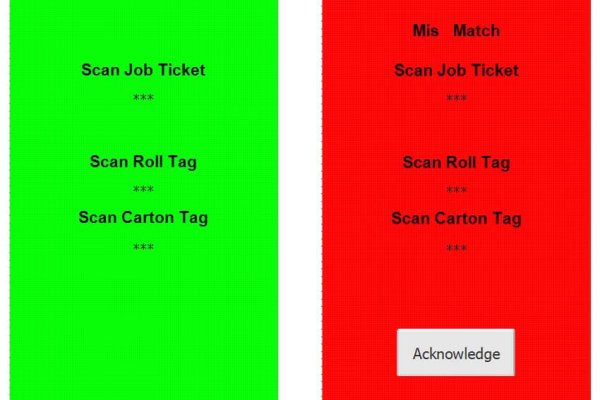

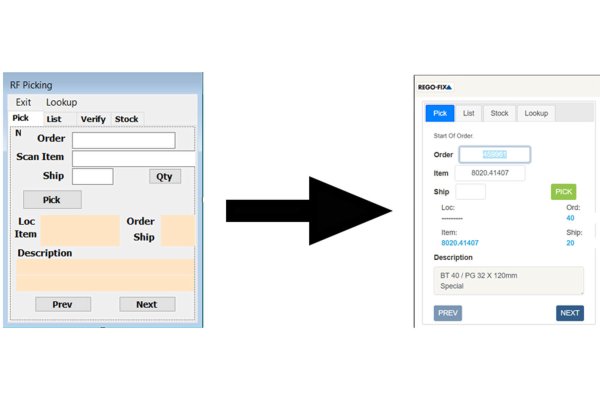

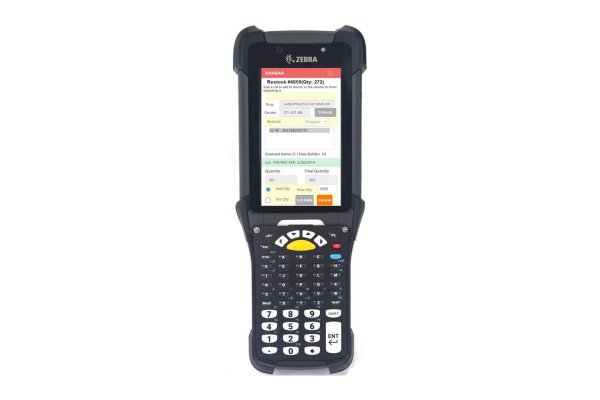

Tracking certain products can be difficult, especially when they are large, coils of steel. In this Customer Soution, we worked with one of our long-time customers to automate the receiving of their steel coils as well as create a database with the location of each coil